In the intricate dance of construction projects, every misstep can lead to costly delays and reworks. Yet, amidst the complexity of mechanical, electrical, and plumbing (MEP) systems lies a powerful tool often overlooked: effective MEP shop drawings. These meticulously crafted blueprints serve as the roadmap for contractors, guiding them through the labyrinth of pipes, ducts, and wires with precision. In our quest to demystify the construction process, we delve into the pivotal role of MEP shop drawings in minimizing reworks and delays.

Understanding MEP Shop Drawings: The Backbone of Building Coordination

In the complex world of construction, precise planning and flawless coordination are essential for success. MEP shop drawings play a critical role in achieving this by providing a detailed roadmap for the vital Mechanical, Electrical, and Plumbing (MEP) systems within a building.

What are MEP Shop Drawings?

MEP shop drawings are essentially technical illustrations that translate the design intent for the MEP systems into actionable instructions. These detailed documents provide crucial information for both the fabrication and installation phases of the project.

What Information is Included?

MEP shop drawings are comprehensive documents encompassing various elements:

Equipment Layouts

Precise locations of pumps, chillers, boilers, electrical panels, and other major MEP equipment are clearly marked.

Piping and Ductwork Systems

Detailed layouts depict the routes and configurations of pipes for water, drainage, gas, and other fluids, along with ductwork configurations for air conditioning and ventilation.

Electrical Components

The drawings illustrate the location and specifications of electrical panels, conduits, wiring paths, and lighting fixtures.

Material Specifications

The type and size of materials used for pipes, ducts, electrical wires, and other components are clearly defined.

Detailed Annotations

Notes and specifications provide additional clarification regarding installation procedures, clearances, and other essential details.

Read more: Different Types of Mechanical, Electrical, and Plumbing - MEP Drawings

Why are MEP Shop Drawings Important?

Think of them as the bridge between the blueprint and the bricks and mortar. MEP shop drawings offer several key benefits:

Accurate Fabrication

The drawings provide precise measurements, material specifications, and component details for manufacturers and fabricators of pipes, ducts, electrical panels, and other MEP components. This ensures everything is built to exact specifications and fits seamlessly within the building's design.

Efficient Installation

Detailed layouts depict the locations of equipment, piping routes, ductwork configurations, and electrical wiring paths. With this clear roadmap, contractors can install the MEP systems efficiently, minimizing errors and ensuring a well-coordinated network.

Clash Detection

By visualizing the entire MEP system in detail, potential clashes between different components can be identified before construction even begins. This proactive approach helps to avoid costly rework later in the project, saving both time and money.

Improved Communication

MEP shop drawings act as a common language for everyone involved in the project – architects, engineers, and contractors. By referring to the same set of drawings, all parties can understand the design intent and ensure they're working towards the same goal.

The Impact of Inaccurate MEP Shop Drawings: A Recipe for Delays and Cost Overruns

When it comes to MEP shop drawings, inaccuracies can create significant problems down the line. Let's delve into the two major consequences: reworks and delays, and their financial repercussions.

Reworks and Delays

Errors or discrepancies in MEP shop drawings can throw a wrench into the construction schedule, causing delays and requiring rework. Here's how:

Clashes

Imagine electrical conduit planned to run directly through a designated duct location. This clash would necessitate rerouting one system, impacting both the original installation schedule and the downstream work that relied on its completion.

Incorrect Dimensions

Miscalculated pipe sizes or misplaced equipment layouts can lead to situations where prefabricated elements simply don't fit the designated space. This requires modifications at the construction site, delaying installation and potentially affecting other trades.

Missing Information

Incomplete drawings lacking crucial details like hanger locations or connection points can stall installation until the information is clarified. This back-and-forth communication adds time to the project timeline.

Cost Overruns

The financial impact of inaccurate shop drawings can be substantial. Reworks due to clashes or incorrect dimensions translate to wasted labor hours, additional material costs, and potential delays in project completion. Schedule extensions may incur penalties or necessitate overtime work, further inflating the budget. Additionally, inaccurate drawings can lead to:

Material Wastage

Prefabricated elements that don't fit or need modification often result in scraped materials, adding unnecessary expense.

Change Orders

The need for rework due to drawing errors often necessitates changing orders, impacting the project budget and potentially straining relationships with subcontractors.

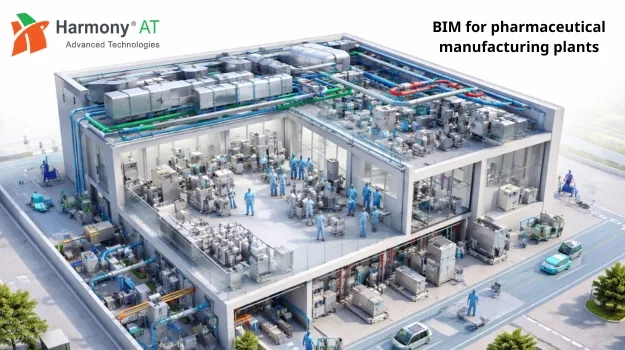

MEP Shop Drawings Services from Harmony AT

Building a successful project hinge on meticulous planning and flawless execution, especially when it comes to the intricate MEP (Mechanical, Electrical, and Plumbing) systems. At Harmony AT, we offer comprehensive MEP shop drawing services to ensure your project runs smoothly and efficiently. Our MEP Shop Drawing Services Encompass:

Mechanical Shop Drawings

Our team of experts creates detailed illustrations for all your mechanical equipment, including pumps, chillers, boilers, and HVAC systems. These drawings provide precise specifications for fabrication and installation, ensuring a seamless integration into your building's design.

Read more: Mechanical Shop Drawings: What They Are and How They Benefit Your Projects

Electrical Shop Drawings

We meticulously map out your electrical system, detailing the location and specifications of electrical panels, conduits, wiring paths, and lighting fixtures. This ensures a safe and efficient electrical layout that meets all code requirements.

Read more: Electrical BIM Modeling Services: Reduce Costs and Get Electrical Installation

Plumbing Shop Drawings

Our plumbing shop drawings provide a clear picture of your water supply, drainage, and waste systems. These drawings specify pipe sizes, materials, and routing, guaranteeing a properly functioning and code-compliant plumbing network.

Read more: Take Advantage of Revit BIM to Design Plumbing Systems for Easy MEP Installation.

HVAC Duct Shop Drawings

For optimal airflow and temperature control, we create detailed shop drawings for your HVAC ductwork. These drawings illustrate the precise layout and dimensions of ducts, ensuring proper air distribution throughout your building.

Read more: Optimize results through streamlined design with the precise HVAC BIM modeling services

Piping Shop Drawings

Whether it's for water, gas, or other fluids, our piping shop drawings provide comprehensive details on pipe sizes, materials, and routing. This ensures a leak-free and efficient piping system that meets all relevant building codes.

Fire Protection Shop Drawings

Harmony AT offers fire protection shop drawings that detail sprinkler systems, fire alarms, and other critical fire suppression equipment. These drawings ensure compliance with building codes and contribute to a safe building environment.

By partnering with Harmony AT for your MEP shop drawings, you benefit from a single point of contact, streamlined communication, and a team dedicated to delivering accurate and efficient documentation. Contact us today to discuss your specific needs and experience the Harmony AT difference.

Categories