Our experts assist you with all your design and programming needs.

The PLC (Programmable Logic Controller) is the core of any industrial automation, controlling the entire operation of machines, plants, and processes in a desired sequence. PLCs control all system inputs and outputs, and the controller integrates with HMIs to control and monitor the manufacturing line more efficiently. In addition, PLCs receive input from sensors, switches, user inputs, HMIs, and other integrated parts of the production line and then control the outputs to automate product creation.

With over 5 years of experience in Industrial Programming for various industries, we utilize our real-world experience and knowledge of manufacturing processes to program custom Industrial Programming to operate effectively and provide support as well as troubleshooting. Our strict adherence to the latest programming standards and technology updates allows us to continuously develop our applications in this ever-changing market.

We specialise in

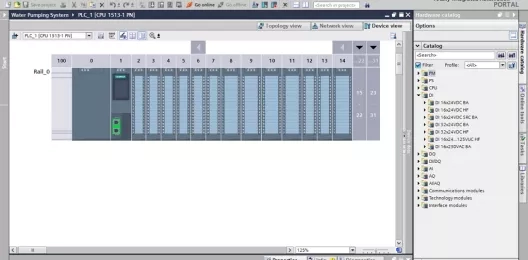

PLC programming & configuration

We are capable of providing complete PLC programming services, from concept to commissioning, written in an easy-to-understand language with full symbol and operation documentation. The machine interface offers innovative and intuitive levels of control as well as information about the current sequence step.

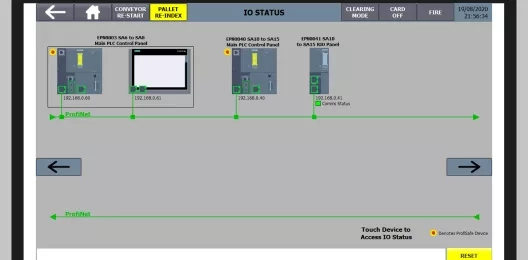

HMI programming

With experienced programmers who are well versed in major programming technologies, Harmony AT develops code to the most rigorous standards. Our Human-Machine Interface (HMI) programming not only ensures that your process system is effectively automated, but it also connects with your existing systems and programming.

Monitoring & management system programming

We develop software for monitoring all factors critical to production, allowing for real-time reporting, control, and monitoring of PLC data and energy usage in factories. This helps you achieve stable and high-value-added production, safety and management of that system's operations, and enhancements for more sophisticated operations.

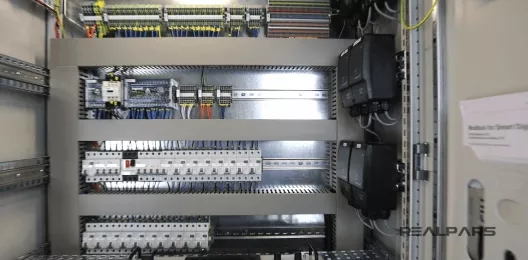

PLC control cabinet design

We offer an extensive portfolio of industrial control cabinets to address the complicated and changing needs of our customers. Our affordable and efficient solutions will assist you in increasing automation and improving workflows. No matter what you're searching for, our team of skilled designers will help you every step of the way.

Control system design

We offer application-appropriate system designs, from simple stand-alone systems to networks of disparate systems communicating wirelessly or over a network to enterprise-grade control systems that control complex operations on a solid fiber backbone.

Why Harmony AT?

After working with all the leading industrial automation product suppliers, we have a deep understanding of the best points to choose the right fit and are also good at training and documentation.

Affordable prices for companies of all sizes

Our experts carry out projects at competitive rates from Vietnam which means you will pay less for the same quality provided by local experts

Adaptability of experts

Our talented engineers can adapt to any type of PLC without sacrificing productivity or operating speed

Communication & timezone

We can communicate with clients fluently in English, German, and Japanese and implement your project on time, even if you’ve got a significant time difference with us.

Legal protection

We strictly adhere to NDA specifications protecting our clients' trade and production secrets, which is critical to industrial espionage.