Customer:

A leading German factory specializing in the supply and manufacture of water treatment equipment (Heavy Industrial sector).

Challenge:

Converting paper-based design data into a streamlined, digital workflow for improved efficiency and standardization.

Scope of Work:

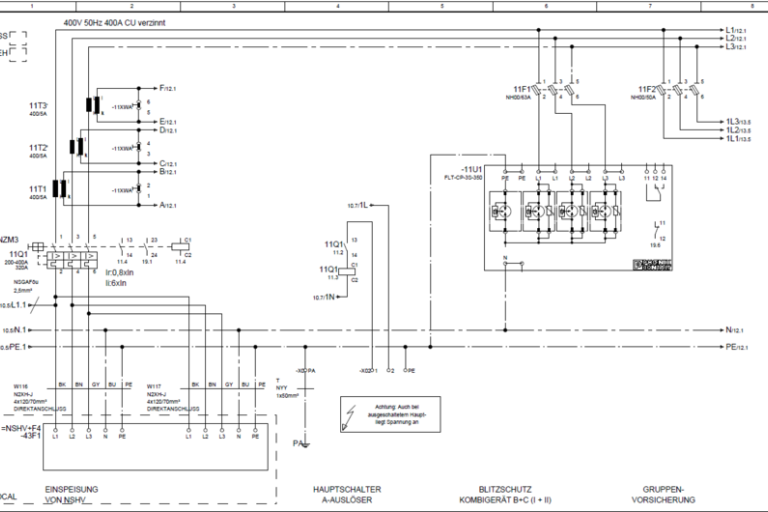

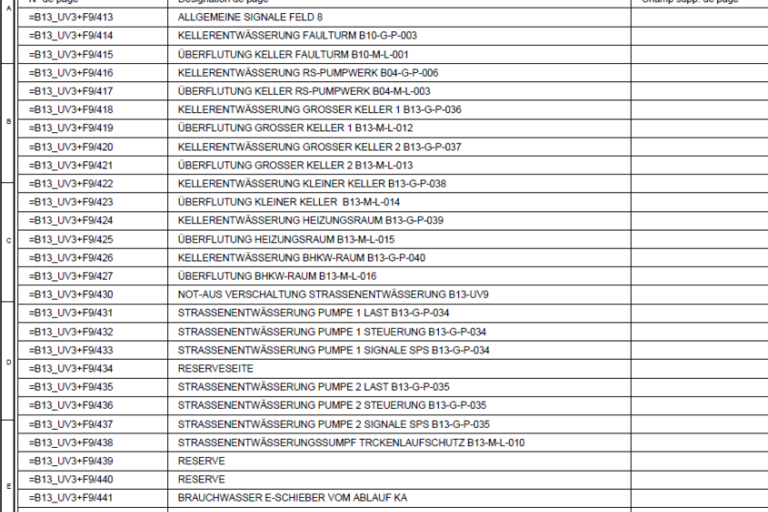

Data Conversion: Transforming intricate control system breakdowns from PDFs into Eplan software format.

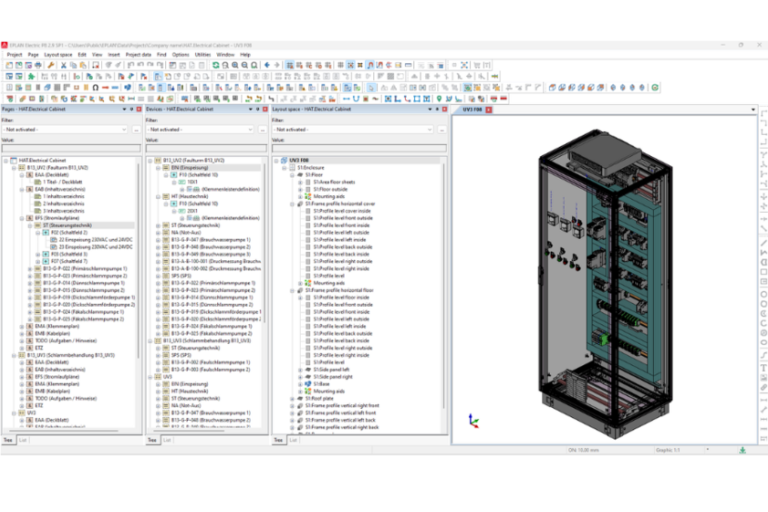

2D to 3D Model Creation: Developing a comprehensive 3D model based on the converted 2D drawings, adhering to the customer's design standards.

Symbol Customization: Creating a library of custom symbols for both electrical drawings and 3D models, fostering consistency and clarity.

Solution:

Breakdown Analysis: Our team meticulously analyzed the customer's control system breakdowns, gaining a deep understanding of the electrical configurations and component specifications.

2D to 3D Reconstruction: Leveraging our expertise in Eplan, we meticulously reconstructed the electrical drawings into a robust, digitally editable format, aligned with the client's established design standards.

3D Modeling Excellence: Based on the enhanced 2D drawings, we developed a detailed and accurate 3D model, providing a visually impactful representation of the entire control system.

Seamless Data Synchronization: We established a seamless connection between the 2D design data and the corresponding 3D panel, ensuring perfect consistency and real-time updates throughout the design and production phases.

Results:

Optimized Workflow: The customer now benefits from a streamlined design process, where data seamlessly flows from initial concept to purchase orders, eliminating redundancy and errors.

Enhanced Standardization: By consolidating design data into a single, centralized system, the client has achieved higher design consistency and clarity, improving communication and collaboration across departments.

Improved Efficiency: The transition to a digital workflow has significantly reduced design and production time, allowing the customer to respond to market demands with greater agility.