In the intricate web of modern construction projects, Mechanical, Electrical, and Plumbing (MEP) systems are the unsung heroes, ensuring the functionality, comfort, and safety of buildings. However, the seamless integration of these vital systems doesn't happen by chance; it requires meticulous coordination. In this comprehensive guide, we embark on a journey to explore the significance of MEP coordination. From understanding its fundamental principles to unraveling its impact on project timelines, budgets, and quality, we'll delve into the intricacies of MEP coordination and unveil its critical role in the success of construction endeavors.

What is MEP Coordination?

MEP coordination is the process of planning and designing the mechanical, electrical, and plumbing systems in a building in a coordinated way so that they fit together properly and don't conflict with each other.

The mechanical systems include things like HVAC (heating, ventilation, and air conditioning) ductwork and piping. The electrical systems include things like wiring, outlets, and light fixtures. And the plumbing includes water pipes, drain pipes, and fixtures like toilets and sinks.

If these various systems are not coordinated properly during the design phase of a construction project, it can lead to problems when installing them. For example, HVAC ducts and electrical cables could be designed to go in the same space, creating issues during installation. Or water pipes could be placed too close to electrical wiring.

Benefits of MEP Coordination

MEP coordination is the process of ensuring that all of the mechanical, electrical, and plumbing (MEP) systems in a building are designed and installed in a way that they don't interfere with each other. This is important, not just for functionality, but for a multitude of benefits that ripple throughout the construction process and beyond.

Clash-Free

Imagine a meticulously planned plumbing layout colliding with an electrical conduit, or a ventilation duct snaking through the space designated for an elevator shaft. These clashes, unfortunately common in uncoordinated projects, lead to costly rework, delays, and frustration. MEP coordination tackles this head-on by identifying and resolving these conflicts before they materialize, using tools like 3D modeling and clash detection software. The result? A harmonious interplay of systems, where pipes, wires, and ducts dance together in perfect rhythm, ensuring smooth construction and avoiding costly headaches.

Cost Savings

The financial benefits of MEP coordination are undeniable. By eliminating clashes and rework, projects experience significant cost reductions. Less wasted materials, fewer change orders, and faster construction timelines all contribute to a leaner, more efficient budget. Additionally, well-coordinated MEP systems often lead to improved energy efficiency, further reducing operational costs and contributing to a sustainable future.

Collaboration Crescendo

MEP coordination fosters a spirit of collaboration among all stakeholders involved in the construction process. Architects, engineers, contractors, and subcontractors work together from the early stages, ensuring everyone is on the same page. This open communication and shared understanding lead to a smoother workflow, reduced errors, and improved decision-making.

Beyond the Bricks and Mortar

The benefits of MEP coordination extend far beyond the construction site. Well-coordinated systems contribute to enhanced occupant comfort and safety. Efficient HVAC systems ensure optimal temperature control, while properly designed plumbing and electrical systems minimize the risk of leaks and accidents. Ultimately, MEP coordination plays a vital role in creating buildings that are not just functional, but also enjoyable and healthy places to live, work, and learn.

MEP coordination is not simply a technical exercise; it's an investment in a better built environment.

MEP Coordination: Contrasting Traditional Design with BIM-Based Approaches in Construction

In short, using BIM coordination is better than traditional methods. It helps find and fix problems early, making collaboration smoother and reducing the chance of costly changes later on. This means less risk and better planning for design and construction. The table shows that BIM is especially good for MEP coordination because it improves how we see spaces, detect clashes, and handle design changes.

Guide to Implementing MEP Coordination in BIM-Driven Design

Here's a roadmap to implement effective MEP coordination in your BIM-driven design:

1. Establish a Collaborative Framework

Define Roles and Responsibilities: Clearly outline the roles and responsibilities of each stakeholder involved in MEP coordination, from architects and engineers to contractors and subcontractors. Open communication and a shared understanding are key.

Set Up Communication Channels: Establish clear communication channels, such as regular meetings, cloud-based collaboration platforms, and issue tracking systems, to facilitate seamless information exchange and real-time problem-solving.

2. Leverage the Power of BIM Tools

Utilize Standardized Templates: Employ standardized BIM templates for MEP components to ensure consistency and interoperability between different software programs.

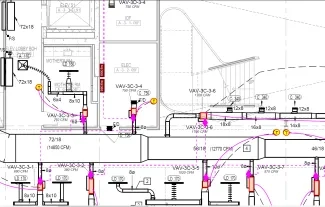

Embrace Clash Detection Software: Implement specialized clash detection software to identify and resolve potential conflicts between MEP systems early in the design process, saving time and money.

Optimize Model Levels of Detail (LOD): Define appropriate LODs for each stage of the project, ensuring sufficient detail for coordination without overloading the model and hindering performance.

3. Foster a Continuous Feedback Loop

Regularly Review and Update Models: Schedule regular reviews of BIM models by all stakeholders to identify and address any discrepancies or potential issues before they escalate.

Document and Learn from Clashes: Maintain a record of identified clashes and their resolutions to build a knowledge base for future projects and continuously improve coordination processes.

4. Consider Additional Strategies

Prefabrication and Modularization: Explore opportunities for prefabrication and modularization of MEP components to improve accuracy, efficiency, and on-site installation.

4D and 5D BIM: Utilize 4D BIM for construction sequencing and 5D BIM for cost estimation to further enhance project planning and control.

Harmony AT's MEP BIM Coordination Services – Your Ultimate Solution!

Coordinating MEP designs is crucial but complex. Therefore, let Harmony AT handle it for your next project! Our BIM coordination specialists combine all designs into one digital model. This digital model then allows for comprehensive clash detection before construction begins.

Furthermore, using advanced software, we thoroughly check for overlaps between systems like pipework, ducting and cables. Consequently, comprehensive clash reports and resolutions help ensure a smooth build. In addition to clashes, our coordination services develop construction schedules and optimized installation plans.

Moreover, spatial coordination drawings also confirm fitting of all components in the building design. As a result, outsource to Harmony AT and benefit from our BIM expertise and specialist tools. Subsequently, our affordable pricing makes us suitable for all project sizes.

To discuss how our MEP BIM coordination services can benefit your next construction project, contact us here. Our team would be happy to provide a free consultation and quotation. Working with us is the simple solution to a coordinated, clash-free build.

Categories