In the intricate landscape of engineering projects, one often encounters the indispensable realm of Mechanical Shop Drawings. These meticulous blueprints serve as the backbone of any mechanical endeavor, providing detailed insights into component configurations, material specifications, and assembly processes. In this article, we'll explore the different types of mechanical shop drawings and shed light on how they contribute to the success of your project. From ensuring precision in manufacturing to facilitating smooth installation, these drawings play a crucial role in streamlining workflows and achieving superior project outcomes.

What are Mechanical Shop Drawings?

Mechanical shop drawings are detailed technical illustrations that depict the specifications, dimensions, and assembly instructions for mechanical components within a project. These drawings serve as a comprehensive guide for fabricators, manufacturers, installers, and other stakeholders involved in the construction or engineering process.

Besides, mechanical shop drawings provide precise information about the design, materials, tolerances, and installation methods of various mechanical elements, such as machinery, equipment, piping systems, HVAC (heating, ventilation, and air conditioning) systems, and structural components. They are typically created using computer-aided design (CAD) software and play a crucial role in ensuring the accuracy, quality, and functionality of mechanical systems within a project.

The Role of Mechanical Shop Drawings in Construction Projects

Mechanical shop drawings act as the backbone for a project's HVAC (Heating, Ventilation, and Air Conditioning) system installation. These detailed documents ensure a smooth and efficient construction process by serving several crucial roles:

Detailed Specifications

Shop drawings provide precise measurements for all HVAC components, including ductwork, pipes, equipment dimensions, and clearances. This ensures that all parts fit together correctly and function as intended. Additionally, they specify material types, finishes, and installation requirements.

Coordination Among Trades

Construction projects involve multiple teams working on different systems. Mechanical shop drawings clearly illustrate how the HVAC system interacts with electrical wiring, plumbing lines, and structural elements. This helps identify and avoid potential clashes during construction, saving time and money.

Facilitating Approvals and Permits

Building departments often require detailed shop drawings before issuing permits for construction. The comprehensive nature of these drawings, demonstrating compliance with building codes and regulations, streamlines the approval process.

Guiding Construction and Installation

Shop drawings serve as a clear roadmap for contractors and technicians during installation. The drawings provide step-by-step instructions for assembling the HVAC system, ensuring proper placement, connections, and adherence to safety protocols. This reduces the risk of errors and rework, leading to a more efficient and high-quality installation.

Why Accurate Mechanical Shop Drawings Matter on Your Build

Mechanical Shop Drawings serve as the blueprint for the implementation of mechanical systems within construction projects, playing a crucial role in ensuring precision, efficiency, and cost-effectiveness throughout the entire process.

Here's why accuracy in Mechanical Shop Drawings is paramount

Precision in Mechanical Shop Drawings

Accurate Mechanical Shop Drawings are fundamental for ensuring that mechanical systems, such as HVAC, plumbing, and fire protection, are designed and installed correctly. Precision in these drawings is essential to depict the exact dimensions, specifications, and layout of the systems, facilitating seamless coordination among various trades and minimizing errors during construction.

Impact on Project Timelines and Costs

The accuracy of Mechanical Shop Drawings directly influences project timelines and costs. When drawings are precise and detailed, contractors can proceed with confidence, knowing exactly how and where each mechanical component should be installed. This reduces the likelihood of rework, or delays caused by misinterpretations or conflicts between trades, ultimately speeding up the construction process and preventing costly setbacks.

Furthermore, accurate drawings enable efficient material procurement and resource allocation, preventing unnecessary expenses associated with ordering incorrect materials or labor overruns due to unforeseen complications.

Examples of Potential Issues Arising from Inaccurate Drawings

Inaccurate or incomplete Mechanical Shop Drawings can lead to a myriad of problems throughout the construction process. For instance:

Coordination Errors

Inadequate coordination between mechanical systems and other building elements may result in clashes or interference during installation, requiring time-consuming modifications and delaying the project.

Performance Issues

Incorrectly sized or positioned mechanical components can compromise the functionality and efficiency of systems, leading to suboptimal performance and increased energy consumption.

Safety Concerns

Flawed drawings may overlook essential safety requirements or fail to account for emergency egress routes, posing risks to occupants and contravening building codes and regulations.

Legal and Financial Ramifications

Discrepancies between contractual obligations and actual installations due to inaccurate drawings can lead to disputes, litigation, and additional costs for all parties involved.

By ensuring precision, these drawings facilitate smooth project execution, minimize risks, and contribute to the overall success of construction endeavors. Investing in high-quality Mechanical Shop Drawings upfront is, therefore, a prudent decision that yields significant benefits in terms of time, cost, and quality throughout the project lifecycle.

Harmony AT: Your One-Stop Shop for All Your Mechanical Shop Drawing Needs

Harmony AT is a leading provider of exceptional Mechanical Shop Drawings services. We understand the importance of clear, concise, and accurate drawings in ensuring a smooth and efficient construction process. Our team of experienced engineers and designers utilizes the latest technology and industry best practices to deliver high-quality shop drawings that meet your exact specifications.

Harmony AT offers a comprehensive range of mechanical shop drawings to cater to the diverse needs of engineering and construction projects. Here's a breakdown of the remaining types of drawings Harmony AT might provide:

Assembly Drawings

These drawings illustrate how various components fit together to form a complete mechanical assembly. They provide detailed views of each component's placement, orientation, and interconnections, aiding in understanding the assembly process.

Read more: Assembly Drawing: Importances and Types in Mechanical Engineering

Fabrication Drawings

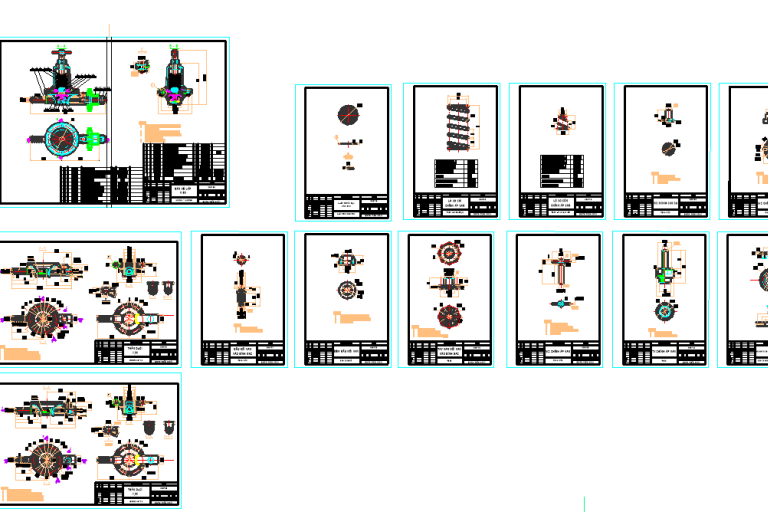

Fabrication drawings provide instructions for manufacturers on how to produce individual components or parts of mechanical systems. They include detailed dimensions, material specifications, machining instructions, and welding symbols to ensure accurate fabrication.

Installation Drawings

Installation drawings guide contractors and installers in placing and integrating mechanical systems within a building or structure. These drawings depict the layout, positioning, and attachment methods of equipment, machinery, and piping systems, facilitating efficient installation processes.

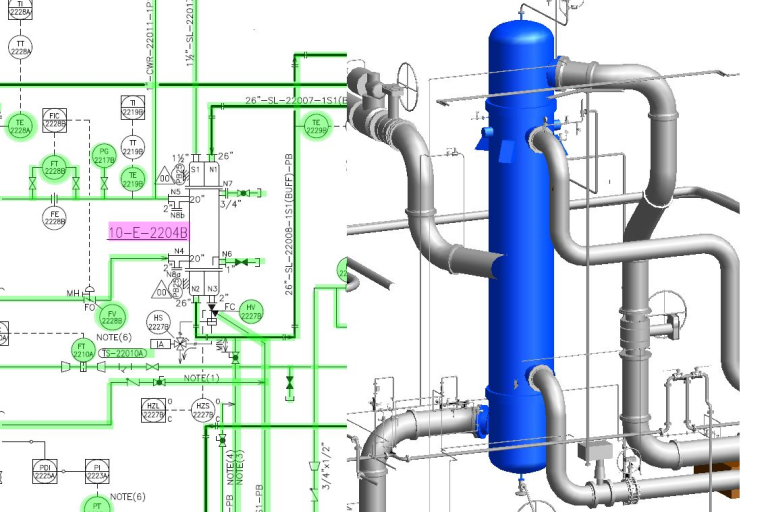

P&ID (Piping and Instrumentation Drawings)

P&ID drawings depict the layout and interconnections of piping systems, along with instrumentation and control devices. They provide a detailed representation of process flow, equipment, valves, fittings, and instrumentation, essential for designing, operating, and maintaining industrial processes.

Read more: P&ID Drawing (Piping & Instrumentation Diagrams): Simple Guide

Patent Drawings

Patent drawings illustrate new inventions or innovations in mechanical engineering. These drawings comply with patent office requirements and include detailed views, dimensions, and annotations to support the patent application process.

Isometric Drawings

Isometric drawings provide a three-dimensional representation of mechanical components or systems, showing all three spatial axes in equal measure. They offer a clear and comprehensive view of the structure, layout, and relationships between various components, aiding in visualization and understanding of complex mechanical systems.

Comprehensive Approach to Drawing Creation

At Harmony AT, we adopt a comprehensive approach to creating Mechanical Shop Drawings. Our process involves thorough analysis and collaboration to understand the project's specifications and requirements fully. We pay meticulous attention to detail, ensuring that every aspect of the mechanical systems is accurately represented in the drawings. By employing advanced software and tools, we streamline the drafting process, resulting in timely delivery without compromising on quality.

Experience Across Various Projects and Industries

Having worked on a wide range of construction projects across different industries, Harmony AT brings invaluable experience to every project we undertake. Whether it's commercial buildings, residential complexes, industrial facilities, or infrastructure projects, our team has the expertise to handle diverse requirements and challenges effectively. Our proven track record of successful project deliveries speaks volumes about our capabilities and reliability.

Contact Harmony AT today to discuss your Mechanical Shop Drawings needs and experience the difference precision makes.

Conclusion

Mechanical Shop Drawings stand as the cornerstone of successful construction projects, underscoring the critical need for precision and accuracy in their creation. As the blueprint for mechanical systems, these drawings play a pivotal role in ensuring seamless coordination, efficient installation, and optimal performance of HVAC, plumbing, and fire protection systems.

Categories