The coal processing industry is highly complex, involving multiple interconnected systems such as screening plants, thickener tanks, and drying equipment. Traditional 2D design often leads to errors and delays. 3D BIM offers a powerful solution by digitally visualizing the entire project, improving design accuracy, coordination, and overall efficiency. This blog explores how Harmony AT applies comprehensive 3D BIM modeling to coal processing complexes and supporting infrastructure, improving design accuracy, multidisciplinary coordination, and project efficiency.

Challenges in Designing and Constructing Coal Processing Complexes

Designing and building coal processing complexes is a highly intricate process, requiring precise coordination among multiple technical disciplines.

Complex Structure and Multi-System Integration

Coal processing plants comprise numerous interdependent systems that must work seamlessly together. From material transport conveyors and water circulation pipelines to filtration, drying, and sludge handling equipment, every element must fit within the overall layout. This spatial complexity makes it challenging to plan and coordinate construction using traditional 2D drawings alone, increasing the risk of design inconsistencies and installation conflicts.

Multi-Disciplinary Coordination Difficulties

These projects involve several design teams, including structural, MEP, process engineering, and infrastructure specialists. Each team may use different standards and software platforms, making cross-disciplinary coordination difficult. Without a unified modeling approach, conflicts between piping, structural elements, and process equipment often go unnoticed until construction, causing delays and additional costs.

Accuracy and Safety Requirements

Coal processing facilities operate under strict industrial safety standards and require precise construction tolerances. Design or installation errors can affect operational efficiency, equipment performance, and worker safety. Ensuring high accuracy is therefore critical throughout the project lifecycle.

Limitations of Traditional 2D Design

Traditional 2D design methods fail to provide a complete view of the spatial relationships among systems, which can hinder stakeholder communication and complicated construction planning. The resulting lack of clarity often leads to rework, cost overruns, and schedule delays.

These challenges highlight the need for a more advanced digital solution. 3D BIM modeling enables visualization of the entire coal processing complex, improves coordination among disciplines, and ensures that design, construction, and operational requirements are fully aligned.

Application of 3D BIM for Coal Processing Complexes and Supporting Infrastructure

3D Visualization of the Entire Facility

Instead of relying on fragmented 2D drawings, 3D BIM enables a full digital representation of the coal processing complex — including the main screening plant, preparation building, thickener tanks, filter press and drying systems, raw coal storage, and supporting infrastructure — in three-dimensional space. This allows engineers, contractors, and owners to easily visualize the overall structure, identify complex intersections, and address design conflicts early in the project.

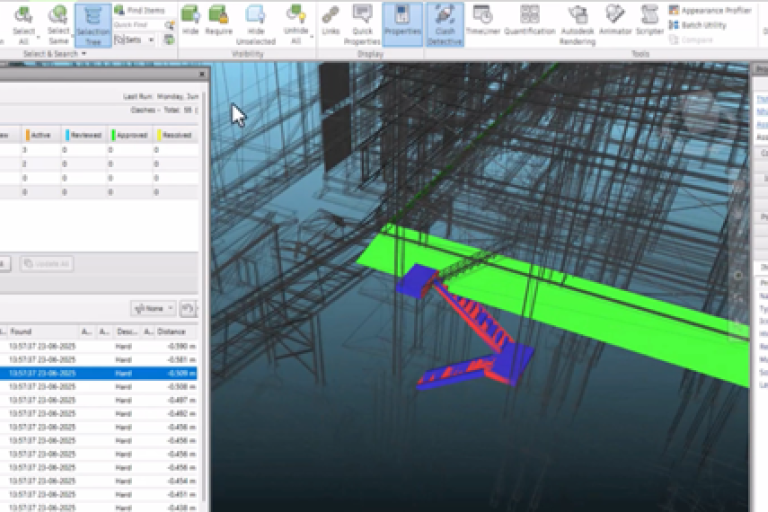

Enhanced Multi-Disciplinary Coordination and Error Reduction

Large-scale projects often face coordination challenges among structural, MEP, process, and infrastructure teams due to the lack of a common platform. 3D BIM integrates data from all disciplines into a single model, facilitating smooth collaboration and enabling early detection and resolution of conflicts through clash detection before construction begins.

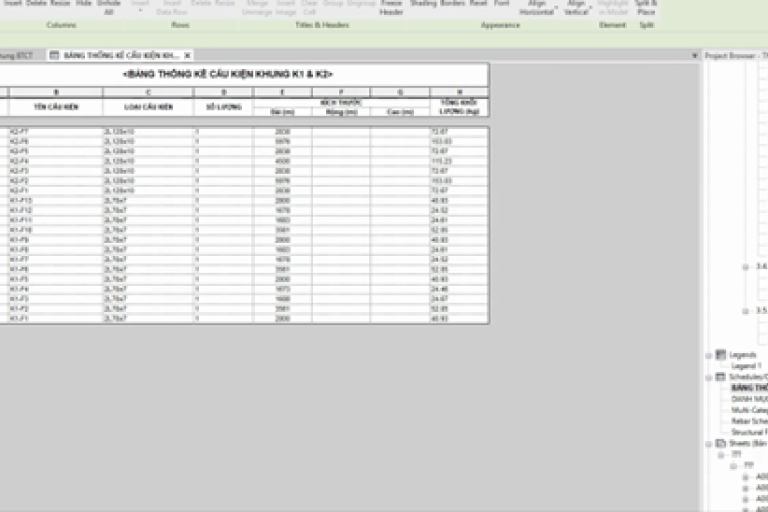

Efficient Quantity, Schedule, and Cost Management

By linking the model directly to material and quantity data, BIM automates material takeoffs, forecasts construction volumes, and enables accurate scheduling. Design changes are updated instantly across the system, ensuring data consistency and helping owners better control costs and construction timelines.

Simulation and Operational Optimization

3D BIM is not only useful during design but also supports the simulation of operational processes, including filter presses, drying, and coal transport systems. These simulations help engineers evaluate real-world performance, optimize equipment layout and energy efficiency, and simplify maintenance once the facility is operational.

Harmony AT’s Capabilities and Project Experience

With years of experience in BIM for the mining and mineral processing industry, Harmony AT has successfully delivered large-scale projects, notably for Vietnam National Coal and Mineral Industries Group (TKV), including the Nam Mau Coal Screening Plant and the Mao Khe Coal Screening Plant. Both projects required high-detail modeling, close multi-disciplinary coordination, and strict technical, safety, and operational standards.

Nam Mau Coal Screening Plant (Quang Ninh)

Type/Grade: Industrial facility – Grade II

Owner: TKV – Nam Mau Coal Company

Scale: 16.85 ha

Layout:

West Zone: Raw coal and dry coking coal storage — main storage and transfer area.

East Zone: Preparation building, main screening plant, thickener tanks, filter press and drying systems, and auxiliary structures.

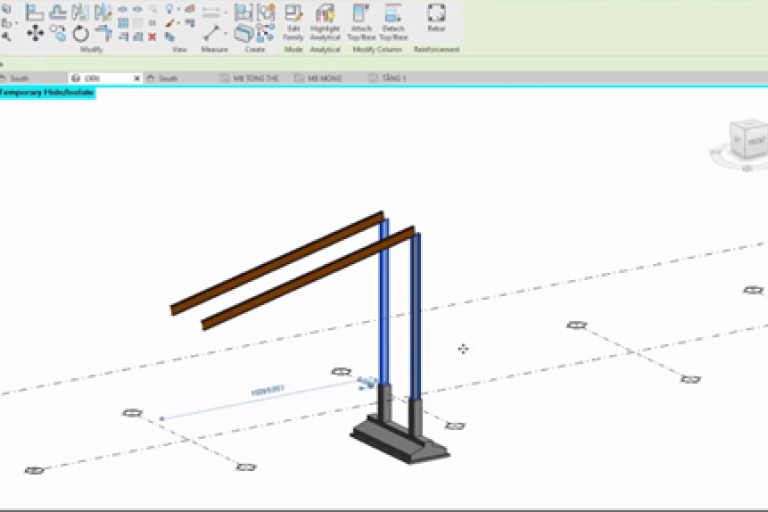

Comprehensive 3D BIM Modeling

Harmony AT developed a detailed 3D BIM model that covered all architectural, structural, and MEP disciplines of the Nam Mau Coal Screening Plant. The model provided a unified digital representation of the entire facility, enabling engineers and project managers to visualize complex spatial relationships and ensure design consistency across all systems.

Clash Detection and Multi-Disciplinary Coordination

Using advanced BIM tools, Harmony AT performed thorough clash detection to identify and resolve design conflicts early in the project. This proactive approach ensured smooth coordination among multiple disciplines, minimized on-site errors, and improved overall project efficiency.

Quantity Takeoff and Drawing Extraction

All material quantities and technical drawings were generated directly from the BIM model. This automation ensured high accuracy in material estimation, reduced manual effort, and maintained consistency between design revisions and construction documentation.

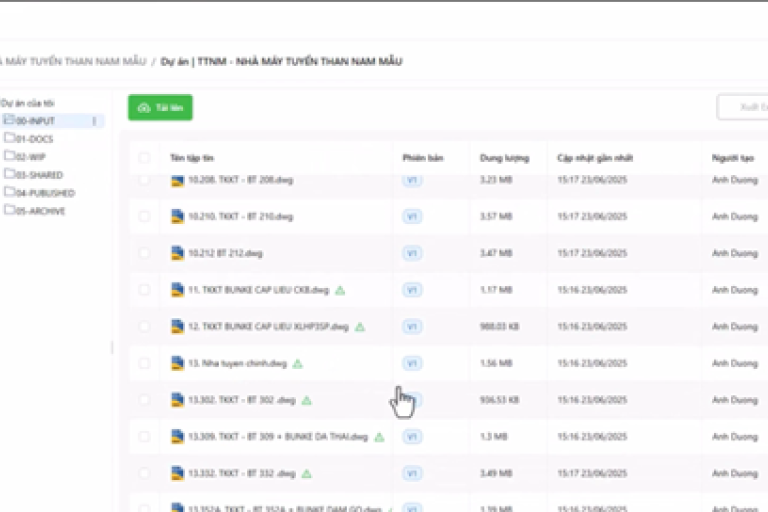

Collaboration on Nova CDE

Design collaboration and model management were conducted on the Nova CDE (Common Data Environment) platform. This digital environment streamlined communication between project stakeholders, provided real-time data synchronization, and maintained version control — ensuring that every team member worked from the latest and most accurate project information.

Mao Khe Coal Screening Plant

Owner: TKV – Mao Khe Coal Company

BIM Scope: From existing condition modeling to full 3D model integration, including:

- Modeling of existing site conditions using survey data.

- 3D modeling of buildings and technical infrastructure, ensuring consistency across disciplines.

- Multi-disciplinary clash detection and complete model consolidation for technical design and construction.

With these projects, Harmony AT has demonstrated advanced 3D BIM expertise in coal mining and processing, delivering detailed models and multi-disciplinary coordination that enhance investment efficiency and optimize project management for TKV.

Typical projects successfully delivered by Harmony AT showcase the company’s proven expertise in BIM outsourcing services for the mining and mineral processing industry. Harmony AT provides comprehensive, end-to-end support, from 3D modeling of complex facilities to multi-disciplinary coordination, clash detection, and quantity takeoff. By leveraging advanced BIM tools, we help clients reduce design errors, optimize construction schedules, manage costs efficiently, and improve operational planning. Partnering with Harmony AT for BIM outsourcing allows mining companies to focus on core operations while relying on high-quality, accurate, and coordinated digital models that enhance project efficiency and streamline decision-making.

Contact Harmony AT today to learn how our BIM outsourcing solutions can optimize your mining and mineral processing projects from design through to operation.

Categories