Sheet metal, that versatile and ever-present material, shapes countless objects in our world, from appliances to car parts. But before these products take form, meticulous planning goes into their design and development. This is where sheet metal design services and modeling come in. These specialized services ensure your product goes from concept to creation smoothly, efficiently, and cost-effectively. In this comprehensive guide, we delve into the intricate world of sheet metal design services and modeling, illuminating the pathways to mastering this vital aspect of modern industry.

Sheet Metal and Harmony AT's Expertise in Sheet Metal Design Services

Sheet metal is a versatile material used in countless applications. It consists of thin pieces of metal, usually between 0.5 and 6 millimeters thick, that have been rolled or flattened from metals like aluminum, steel, or galvanized iron. Therefore, it's a widely used material in construction and manufacturing due to its versatility, affordability, and ease of shaping.

Harmony AT offers a comprehensive suite of sheet metal design services to streamline your product development process. Moreover, our team of experts can handle all aspects of sheet metal design. This ensures your project moves seamlessly from concept to fabrication. Here's a closer look at the services we provide:

2D and 3D Solid Modeling

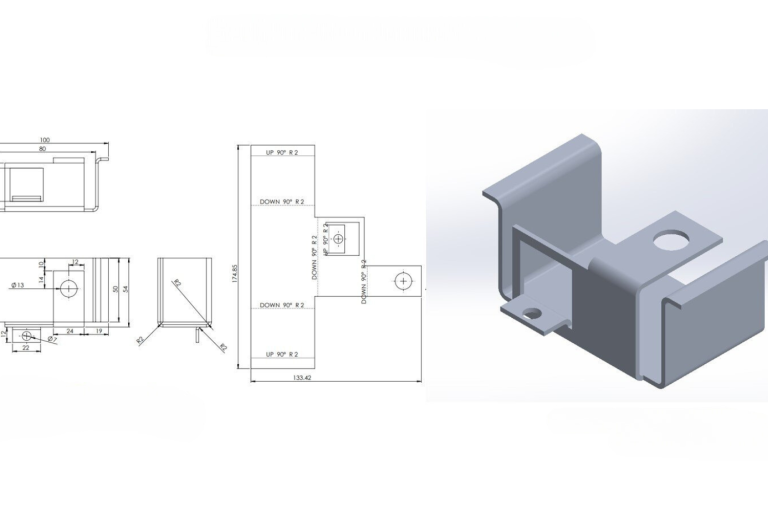

Harmony AT excels at creating detailed 2D flat pattern drawings and 3D solid models of your sheet metal parts and assemblies. These models allow for clear visualization of the final product, enabling early identification and correction of any design issues.

Sheet metal shop drawings

Clear and comprehensive shop drawings are crucial for successful fabrication. So, Harmony AT provides detailed shop drawings complete with dimensions, tolerances, bends, and any other necessary specifications. This ensures your project meets your exact requirements and avoids confusion on the shop floor.

CAD Conversion

Do you have existing designs in outdated formats or PDFs? Not a problem. Harmony AT can meticulously convert your legacy data into modern CAD formats. This not only allows for further design modifications but also ensures seamless integration into your current workflow.

Fabrication Drawings

Harmony AT understands the importance of clear and concise instructions on the shop floor. Therefore, we can also provide traditional 2D fabrication drawings with precise dimensions, bend specifications, and other critical details. This ensures everyone involved in the manufacturing process has the information they need to produce high-quality sheet metal parts.

Bill of Materials (BOM) Generation

Harmony AT takes the guesswork out of material procurement. In addition, we can generate comprehensive BOMs for your sheet metal design projects. These detailed lists specify the type, quantity, and size of sheet metal required. This streamlines your ordering process and guarantees you have all the materials needed for successful fabrication.

Why Sheet Metal Design Services Are Essential?

Expertise and Efficiency

Sheet metal fabrication involves specific techniques and considerations. Besides, design professionals understand factors like bend allowances, formability of different materials, and best practices for manufacturability (DFM) and assembly (DFA). This expertise ensures your design translates smoothly into a functional product without costly mistakes or delays during production.

Quality and Functionality

Through careful planning and analysis, sheet metal design services help create high-quality parts that meet your exact specifications and perform as intended. Furthermore, they can identify potential issues early in the design phase, preventing costly rework and ensuring your final product functions flawlessly.

Communication and Cost Savings

Clear and detailed 2D drawings and 3D models facilitate seamless communication between designers, engineers, and fabricators. This reduces the risk of misinterpretations and errors during production, ultimately saving you time and money.

Streamlined Development

Sheet metal design services can significantly shorten your product development cycle. By leveraging their expertise in creating flat patterns, shop drawings, and BOMs, you can get your project from concept to fabrication much faster.

Innovation and Optimization

Experienced professionals at Harmony AT can unlock the full potential of this material. They'll suggest innovative ways to leverage sheet metal's versatility and recommend alternative materials or fabrication methods to optimize your design, focusing on factors like cost, weight, or strength.

Harmony AT: Your Partner in 3D Sheet Metal Modeling

Harmony AT goes beyond traditional 2D drawings and offers a comprehensive range of 3D sheet metal modeling services to elevate your project:

3D Sheet Metal Modeling

Harmony AT's skilled designers utilize advanced CAD software to create precise 3D models of your individual sheet metal parts. These models go beyond flat patterns, allowing for visualization of bends, folds, and overall product form in a digital environment. This enables early identification of potential design clashes or functionality issues before physical prototypes are built.

3D Sheet Metal Assembly Drawings

Taking it a step further, Harmony AT can generate 3D assembly drawings. These digital representations showcase how all the individual sheet metal parts come together to form the complete product. This visualization is invaluable for identifying potential assembly clashes or identifying areas for improvement in the design's functionality.

3D Sheet Metal Shop Drawings

Harmony AT bridges the gap between design and production with 3D sheet metal shop drawings. These enhanced drawings incorporate the clarity and detail of traditional 2D drawings but leverage the power of 3D visualization. This allows fabricators to easily comprehend complex bends, folds, and part interactions, leading to more efficient and accurate production.

Unveiling the Advantages of 3D Sheet Metal Modeling

Enhanced Design Visualization

3D models provide a realistic representation of your sheet metal parts and assemblies, allowing you to visualize the final product in a virtual environment. This goes beyond flat drawings, enabling you to identify potential design clashes, identify areas for improvement, and ensure all parts function seamlessly together before any physical prototypes are built.

Improved Communication and Collaboration

3D models serve as a universal language, fostering clear communication between designers, engineers, and fabricators. Everyone involved in the project can easily understand the intricacies of the design, leading to fewer misunderstandings and a smoother production process.

Reduced Prototyping Costs

3D models can often replace the need for physical prototypes, saving you time and money. You can virtually test the functionality and fit of your design before committing to expensive physical prototypes.

Streamlined Manufacturing

By leveraging 3D models, Harmony AT can generate highly accurate flat patterns and detailed fabrication drawings. This eliminates the guesswork for fabricators, streamlining the production process and minimizing errors. Additionally, 3D models can be directly integrated with CNC machines, enabling automated cutting, and bending, further enhancing production efficiency.

Reduced Development Costs

While 3D modeling requires an upfront investment, it can significantly reduce costs in the long run. By identifying and resolving design issues early, you minimize the need for costly prototypes and rework. Additionally, 3D models can optimize material usage and fabrication methods, leading to further cost savings.

At Harmony AT, our expertise in sheet metal design services and modeling is amplified by our proficiency with advanced tools and software. Therefore, we harness the power of cutting-edge CAD (Computer-Aided Design) software. These include industry-leading platforms such as SolidWorks, AutoCAD, and CATIA, to craft precise and efficient sheet metal designs. Thanks to these tools, we empower our team to explore innovative solutions, optimize designs for manufacturability, and seamlessly integrate complex components into assemblies. Besides, our mastery of advanced modeling techniques allows us to tackle intricate geometries, simulate real-world conditions. And this ensures the highest levels of accuracy and performance in every project. By leveraging the capabilities of these sophisticated tools, we deliver unparalleled expertise and excellence in sheet metal design services and modeling.

Ready to elevate your sheet metal design projects to new heights of precision and efficiency? Contact Harmony AT today to harness our expertise in advanced design tools and software, ensuring superior results for your next venture. Let us partner with you to bring your sheet metal design visions to life with innovation, expertise, and excellence.

In conclusion, sheet metal design services and modeling are crucial for achieving precision, efficiency, and innovation in manufacturing and construction projects. By leveraging advanced software and tools, these services ensure accurate design, seamless integration, and optimal performance of sheet metal components. This comprehensive guide has highlighted the importance of precise planning, collaboration, and continuous learning to stay ahead in the competitive market. Embracing best practices and technological advancements in sheet metal design can lead to significant cost savings, improved product quality, and faster project completion, ultimately driving success in your projects.

Danh mục