Mechanical, Electrical, and Plumbing (MEP) systems are the backbone of any building, ensuring functionality, safety, and comfort. However, designing and implementing these systems often present unique challenges that can impact project timelines, costs, and overall efficiency. From coordination conflicts between disciplines to navigating complex code requirements, MEP professionals face numerous hurdles that require careful planning and innovative solutions. In this post, we will explore some of the most common issues encountered in MEP projects and offer practical strategies to overcome them, ensuring that your projects run smoothly and deliver optimal results.

Common MEP Challenges in Design

Keeping Up with Technological Advancements

The rapid pace of technological advancements in MEP systems presents a significant challenge for designers and engineers. New innovations in HVAC systems, electrical components, and plumbing technologies emerge regularly, offering improved efficiency, sustainability, and functionality. However, staying updated with these advancements requires continuous learning and adaptation. Failure to incorporate the latest technologies can lead to outdated designs, reduced system performance, and missed opportunities for cost savings. Balancing the integration of cutting-edge technologies with proven solutions is essential to ensure that MEP systems meet both current and future demands.

Solution

The rapid pace of technological advancements in the MEP industry can be daunting, but adopting a proactive approach can mitigate these challenges. Investing in continuous professional development for engineers and designers ensures that the team stays updated with the latest tools and methodologies. Leveraging advanced software solutions, such as BIM (Building Information Modeling), can also streamline the design process, improve accuracy, and reduce rework. Additionally, establishing partnerships with technology providers can give access to cutting-edge tools and early insights into industry trends.

Managing Budgets

Budget management is a critical aspect of MEP design that often proves challenging. MEP systems represent a significant portion of a building's overall construction cost, and any oversights or miscalculations can lead to budget overruns. Designers must balance the need for high-quality, reliable systems with the constraints of limited financial resources. Cost-effective design choices, value engineering, and strategic planning are necessary to manage budgets effectively without compromising the performance or safety of MEP systems. Additionally, unforeseen changes during construction can further strain budgets, making careful planning and contingency strategies essential.

Solution

Budget management is a critical aspect of MEP design, where cost overruns can significantly impact project viability. To address this, incorporating cost estimation tools and BIM models from the project's outset can provide more accurate cost predictions. Integrating value engineering techniques allows for the identification of cost-saving opportunities without compromising quality. Furthermore, adopting modular construction and prefabrication strategies can reduce on-site labor costs, enhance efficiency, and minimize waste.

Creating Clash-Free MEP Designs

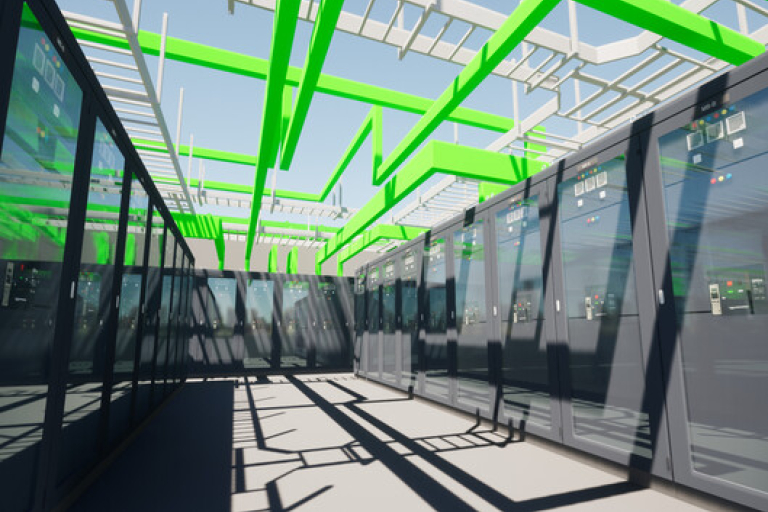

One of the most common challenges in MEP design is ensuring that the various systems—mechanical, electrical, and plumbing - work together seamlessly without physical conflicts. Clashes between systems can lead to significant delays, increased costs, and even safety concerns if not identified and resolved early in the design process. Traditional 2D design methods often fail to capture these potential conflicts, leading to issues during construction. Implementing Building Information Modeling (BIM) for 3D modeling and clash detection is increasingly seen as a vital solution, allowing for the identification and resolution of clashes before construction begins.

Solution

Clashes in MEP designs can lead to costly delays and rework. Implementing a robust BIM coordination process can significantly reduce these issues. By creating detailed 3D models and running clash detection simulations early in the design phase, potential conflicts can be identified and resolved before construction begins. Collaborating closely with all stakeholders, including architects, structural engineers, and contractors, ensures that all systems are well-integrated and that design decisions are made collaboratively to avoid clashes.

Energy Efficiency

Designing MEP systems that are energy-efficient is becoming increasingly important due to rising energy costs and the growing emphasis on sustainability. Achieving energy efficiency involves selecting the right systems and technologies, optimizing system configurations, and considering the building's overall energy consumption. However, this can be challenging, especially when balancing energy efficiency with other factors such as cost, system performance, and occupant comfort. Energy modeling and simulation tools can help designers optimize energy use, but achieving the right balance often requires careful consideration and expertise.

Solution

Designing energy-efficient MEP systems is essential for meeting sustainability goals and reducing operational costs. Utilizing energy modeling software during the design phase helps predict the building's energy performance and allows for optimizing systems to achieve the best efficiency. Incorporating renewable energy sources, such as solar or geothermal systems, and utilizing energy-efficient HVAC and lighting solutions can further enhance the building's overall energy efficiency.

Coordination and Clash Detection

Effective coordination between the different disciplines involved in MEP design is crucial to avoid clashes and ensure that all systems work together harmoniously. However, coordination can be difficult, especially in complex projects with multiple stakeholders and tight schedules. Lack of communication or collaboration between teams can lead to design errors, misalignments, and ultimately costly rework during construction. Advanced BIM tools have made it easier to coordinate designs and detect potential clashes before they become problems, but successful implementation requires commitment from all parties involved.

Solution

Effective coordination among various disciplines is crucial for successful MEP design. Implementing a collaborative workflow, where all stakeholders work within a shared BIM environment, promotes better communication and coordination. Regular coordination meetings and utilizing cloud-based BIM platforms for real-time updates help keep everyone on the same page. By conducting regular clash detection reviews throughout the design process, potential conflicts can be resolved before they escalate, ensuring a smoother construction phase.

Compliance with Standards and Regulations

Navigating the myriads of local, national, and international standards and regulations is a major challenge in MEP design. These regulations cover everything from safety and fire protection to energy efficiency and environmental impact. Compliance is non-negotiable, as failure to meet regulatory requirements can result in legal penalties, project delays, and safety risks. However, keeping up with evolving standards and ensuring that designs adhere to all applicable codes can be complex and time-consuming. MEP professionals must stay informed about the latest regulations and often work closely with code officials to ensure that their designs are fully compliant.

Solution

Navigating the complex landscape of standards and regulations requires a thorough understanding of local codes and international standards. Utilizing BIM software with built-in code compliance checks can help ensure that designs meet the necessary requirements. Regularly updating the team on changes in regulations and engaging with industry experts can also help avoid costly compliance issues. Additionally, collaborating with regulatory authorities during the design phase can help identify potential issues early, allowing for adjustments before construction begins.

Harmony AT offers comprehensive MEP services designed to address the most pressing challenges in the industry. By leveraging advanced BIM technology and a team of highly skilled professionals, Harmony AT ensures that MEP designs are not only up to date with the latest technological advancements but also optimized for cost efficiency and energy performance. Our services include detailed clash detection and coordination, ensuring that all systems integrate seamlessly to avoid costly rework. We prioritize compliance with all relevant standards and regulations, using cutting-edge tools to verify that every aspect of the design meets or exceeds industry requirements. With a commitment to sustainability and innovation, Harmony AT delivers MEP solutions that enhance building performance and reduce operational costs, making us a trusted partner in delivering successful projects.

カテゴリー