Customer:

A Japanese player in the construction industry, offering a diverse range of design, construction, and retail services (Construction, Heavy Industrial sector).

Challenge:

Embarking on a digital transformation for their colossal Coal Crane systems, transitioning from rudimentary 2D training materials to a cutting-edge 3D experience, while simultaneously streamlining production processes and enhancing maintenance protocols.

Scope of Work:

3D Coal Crane Model: Implement a comprehensive and accurate 3D model of the entire Coal Crane system, utilizing Inventor software for unparalleled detail and adhering to stringent Japanese technical requirements.

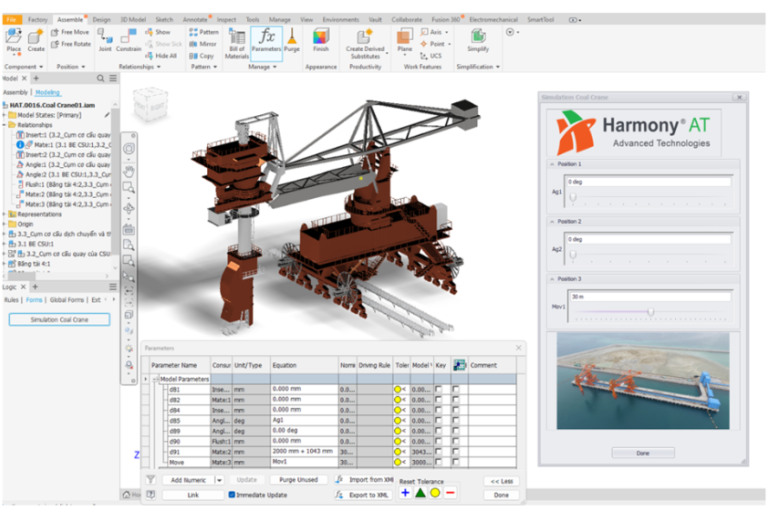

Interactive Motion Simulator: Develop a dedicated tool within AutoCAD, powered by iLogic, that visually showcases the crane's motion limitations in real-time, fostering safety and operational awareness.

Centralized Data Hub: Leverage Vault as a central platform for managing and accessing all 3D models and simulation data, enabling seamless collaboration and real-time data visualization.

Dynamic Parameter Tool: Create a software-integrated tool allowing the customer to independently adjust operational parameters and examine the resulting changes in the crane's motion process, empowering personalized learning and optimization.

Solution:

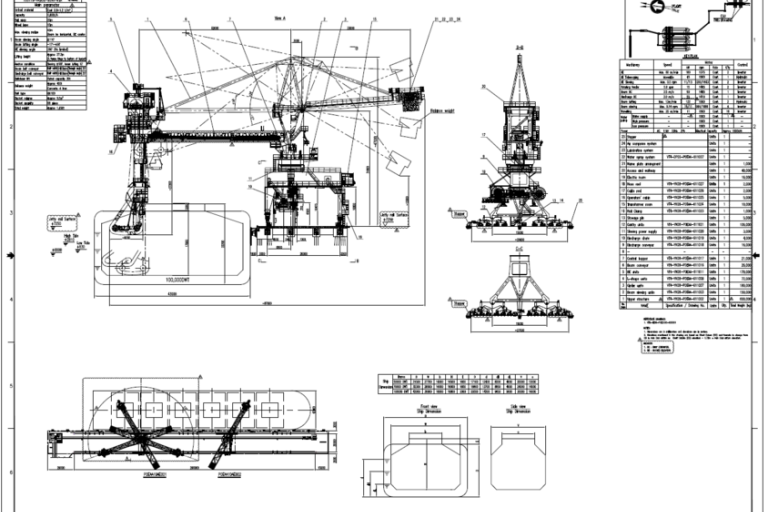

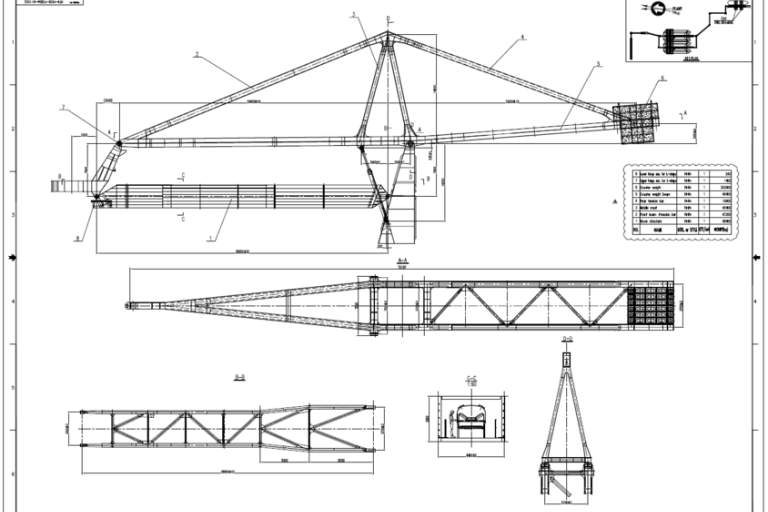

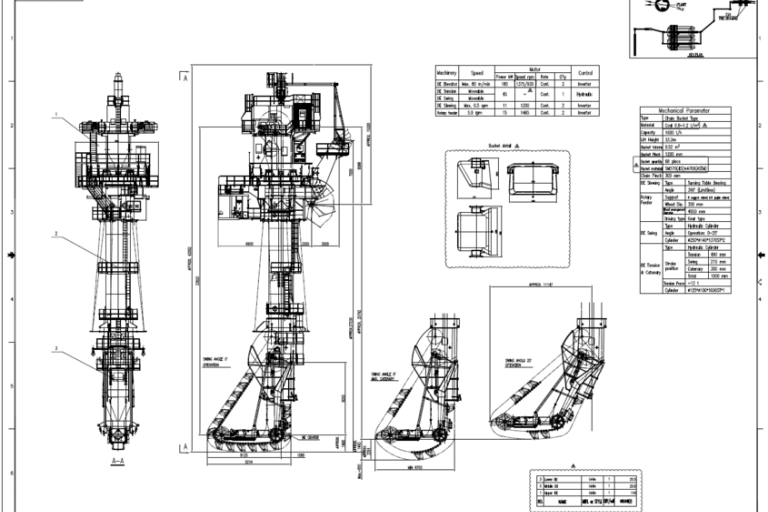

Detailed Breakdown Analysis: Our team meticulously analyzed the intricate breakdown figures of the Coal Crane system, gaining a deep understanding of its functionalities and individual components.

3D Modeling Excellence: Drawing upon our expertise in Japanese technical standards, we crafted a meticulous 3D model of the entire system, encompassing every element with precision and adherence to industry regulations.

Visually Engaging Motion Simulator: Leveraging the power of AutoCAD and iLogic, we developed a dedicated tool that dynamically showcases the crane's motion limitations in real-time, providing operators with valuable insights into safe and efficient operation.

Empowering Data Management: We implemented Vault as a central hub for storing, managing, and accessing all 3D models and simulation data, promoting seamless collaboration and real-time data visualization for training and operational purposes.

Independent Optimization Tool: We created a user-friendly software tool allowing the customer to independently adjust operational parameters and examine the resulting changes in the crane's motion process, fostering continuous learning and personalized optimization.

Results:

Immersive Training Revolution: By replacing static 2D materials with an interactive 3D environment, the customer dramatically improved the effectiveness and engagement of their training programs, leading to enhanced operational efficiency and safety.

Process Optimization through Visualization: The 3D model and data visualization capabilities facilitated detailed analyses of the entire system, allowing for the identification and optimization of production processes, resulting in increased efficiency and reduced downtime.

Predictive Maintenance and Upkeep: Utilizing the insights gleaned from the 3D model and simulation tools, the customer could develop more effective and targeted maintenance strategies, extending the lifespan of their Coal Crane system and minimizing repair costs.

Empowered Learning and Optimization: The independent parameter tool provided the customer with a self-driven platform for continuous learning and process optimization, fostering long-term expertise and adaptability.